Bit of an update,

After finding out I needed a new OS CV joint on Thursday right before our ring trip.. I went into mad panic and frantically sourced not 1 but 2!, making a quick visit to FB Tuning Rich was very helpful in fitting the thing and while it was up on the ramp. bleeding the brakes.. he also kindly moved the fuel cut at 1.76 bar which I have run into a few times recently on slightly more aggressive boost duty settings, while performing lazy 5th gear overtakes.

Once again big thanks to Rich who always helps me out in my times of need!

Today!

A rather savage trip over the mountain on the Isle of Man recently had me boil (in traffic afterwards) my PFC dot4 racing brake fluid that had only been bled threw a month or so before..

Nevertheless this made it abundantly clear to me it was time to do something about this and try to do it properly.

So I set about gathering bits to improve the brake cooling efficiency - which is pretty piss poor on Subaru's in all honesty, and finally today found time to throw it all on the car.

bits used:-

Roo-ducts (US import) - they look like hospital piss pipes or something!

76mm heatproof 2 ply silicon pipe.

102mm neoprene 2 ply pipe

92mm neoprene 2 ply left overs

76mm Revotec exit ducts

Some scrap aluminium plate.

Silicon sealant.

Hamarite under seal with wax-oil

Jubile clips.

Hand full of rivets

Zip ties.... lots and lots of zipties!

First things first.

Mount the wheel arch roo-ducts.. this involved sizing them up and then drilling a few holes and tapping them etc. I read somewhere on a US forum that you needed to space the bottom bolt hole otherwise it causes cracking! so did this too, filled all the drilled/tapped holes with hammerite underseal/waxoil and then bolted them up.

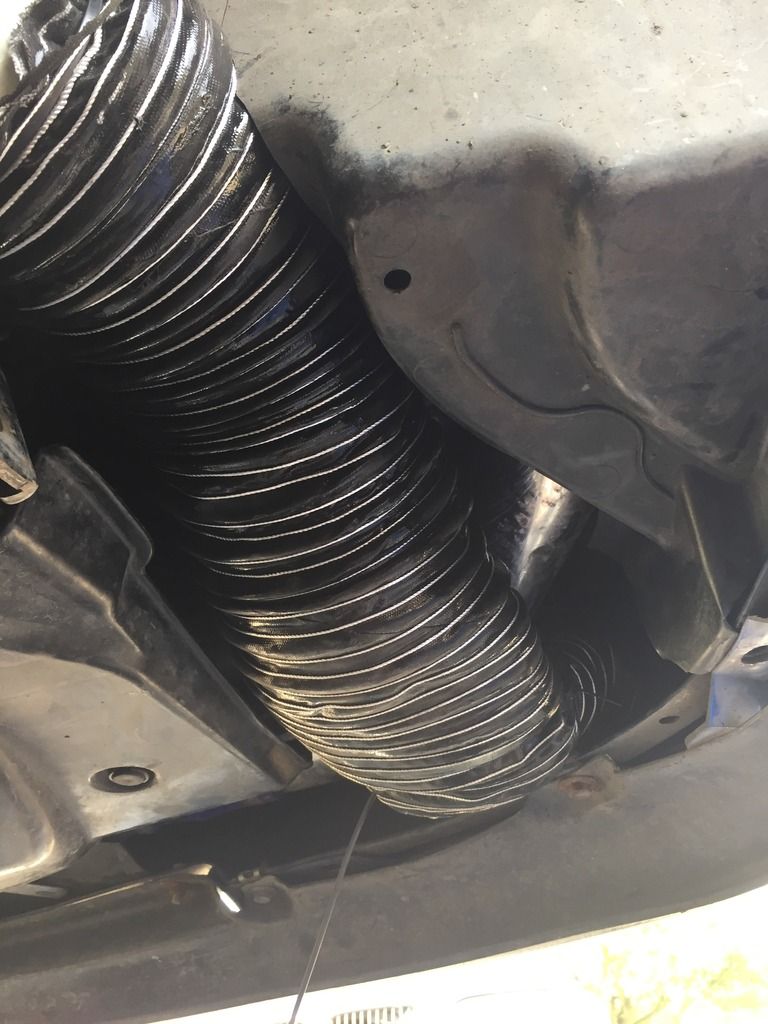

I then fed both sides with 102mm neoprene pipe (which is massive by the way!)

although I was forced to step down the size of the pipework to 92mm on the passenger side due to room and angular constraints presented by the location of the IC pipes and Oil cooler.. very tempted to re-root all of it!

This process involves some trimming of the wheel arch liners (been here before!), silicon sealing the pipe to the existing standard brake duct holes in the front bumper + some zip ties

Once happy with the all the pipework feeding the roo-ducts I started work on fabricating some simple brackets out of some scrap plate aluminium and revotec exit ducts, they ended up looking something like this..

Once fitted look something like this..

Other side with pipework attached

while fitting these was very careful not to interfere with ABS sensor.

Once all in place and lots of revolutions of the steering wheel back and forth by my excellent assistant Handbrake, making sure all was solid I secured a couple of thin strips of rubber to stop any chaffing of the pipe on the coilovers/ ABS sensor.

As you can see once its all back together the clearances are nice!

NS

OS

Clearance to the tyres is a little on the close side!

Needless to say tyres (of a different size!) getting fitted in next few days

Finished..!

Also found time to re trim and fresh piece of grill for behind the oil cooler.

Next project Might be to seal it all in with some kind of bigger improved splitter I think!

Going out for a spirited drive afterwards and quickly measuring the brakes once arriving home, both discs where under 80 degrees C which is very encouraging.

More to follow.