So its been a while since I've updated this thread but thought I'd do a small update,

As many of you know I am paranoid about knocks and slapping noises (not the kinky kind!) but the ones from bores & pistons, and as my car has managed a fair few fairly hard track days.. I am always nice and gentle with it!

I felt it was high time to swap the engine out for something a little less.. "used" It would be fair to say that I have more than had my moneys worth out of the current unit with 2 trips to Spa and 3 trips to the ring + various track days in-between, none of which have been done at standard power levels. So the plunge was made the and the bank violated etc etc, I sourced a low mileage JDM STI engine from a reliable local supplier, that was imported in a standard car and went about purchasing the additional bits and bobs required...

The shopping list included..

Harvey 3 bolt up-pipe to go with my RCM manifold (that has lived on the office floor for a year!)

11mm oil pump (I like a nice lubed engine!)

New gates belt kit, Oil & Filter, Plugs, sealant, Coolant

Rear break pads (PFC items), diff oil and a pair of front wheel bearings (I seem to eat these for some reason!)

Several ££££s later some time was booked with Richard at FB Tuning for the work to be undertaken and the day of reckoning was at hand! I came over all nostalgic driving the car to the workshop knowing that the engine was coming out of her and how good at had been to me, all the pulls on the autobahn, trips to Isle of Man & Germany etc etc, but at least this way I am saving the heart for a later project ^^

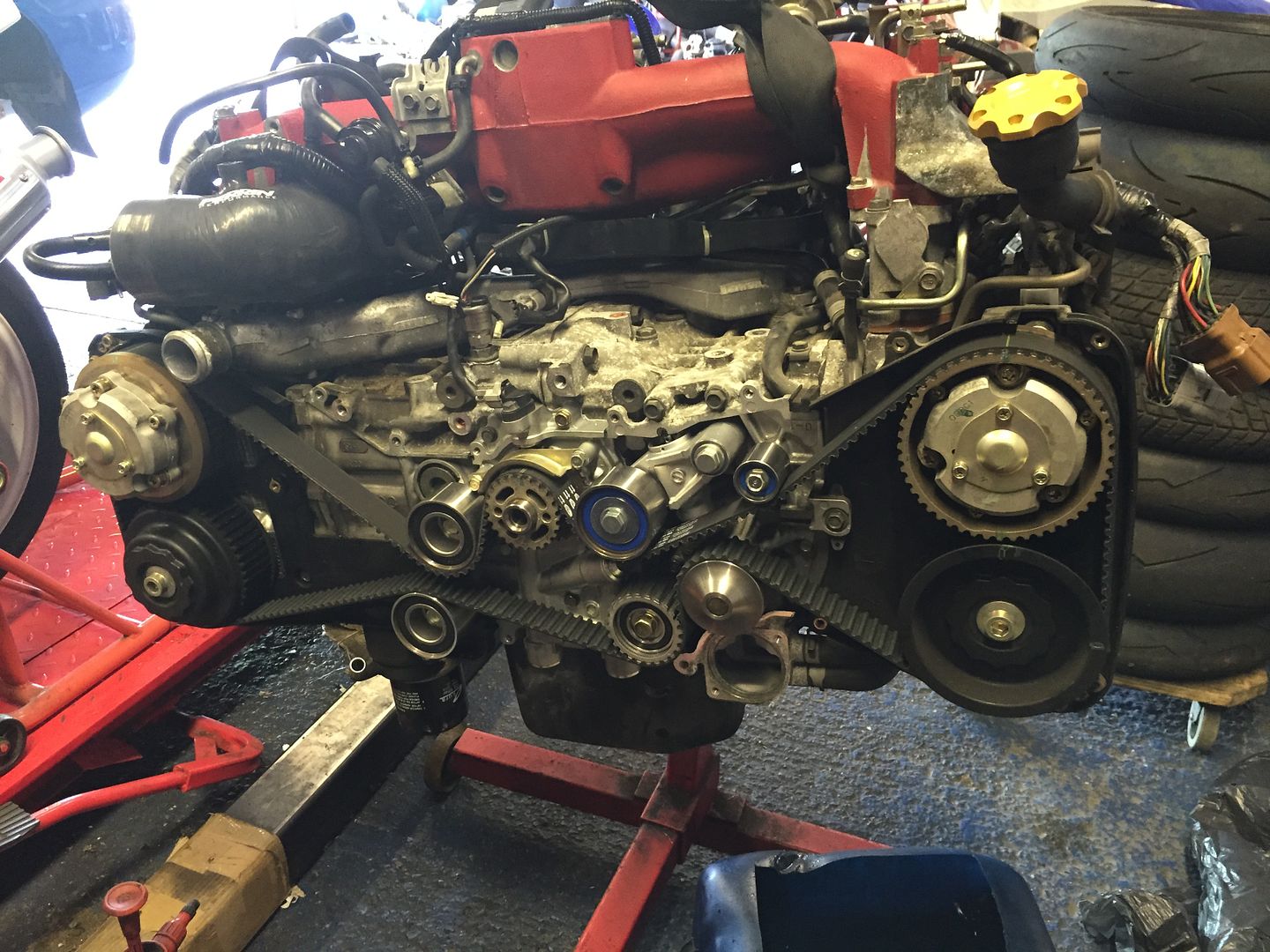

Bits stripped off and getting ready to be pulled!

bye bye old friend!

nooo!

Soon to spin again!

All out in a couple of hours and bits removed an hour later

Much to mine and my wallet's dismay the flywheel and clutch where inspected and deemed to be not worth re-fitting. Looking at the wear on it and the state of the flywheel it simply wasn't worth messing with..

Some nice cracking! Like I said I am always gentle!

So off to Lateral for a new one!

a couple of hours later..

New oil pump prepared and fitted, new timing belt kit and bits and bobs fitted.

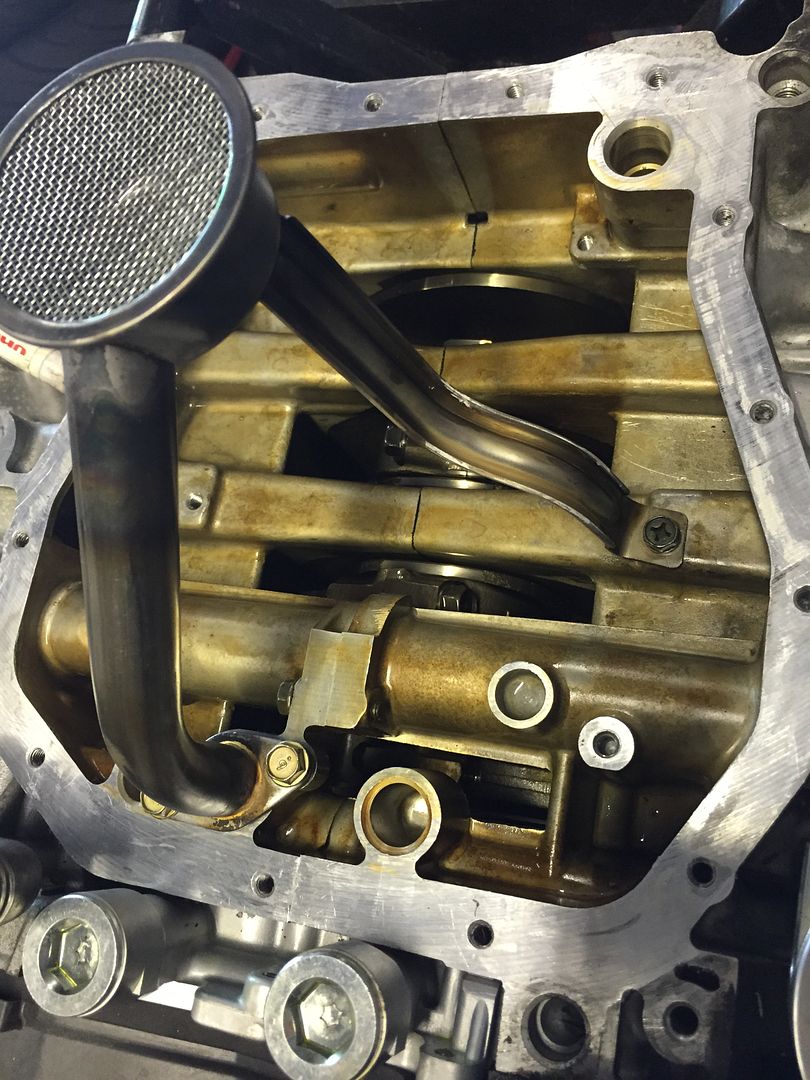

With my current set-up there are quite a few bolt ons to swap over including a group N sump which needed quite a bit of cleaning. The jury is still out on this one as to whether or not the Millers 10w60 Nanotech that I've been using doesn't have enough detergent in it or there was some other underlying issue that caused the blackening visible in the next pics. There where sooty deposits all over the place!

Sump all cleaned, steamed and then blown dry.

Old engine underneath (no windage tray with group N sump!) sooty!

New engine underneath, clean.

Getting there!

We noticed this when re-fitting the radiator. Pretty scary and a potential fire risk. I think it had either got very hot just above manifold or something rubbed against it.

Repaired, cable moved higher up and sorted with a little mod

So up until this point everything had going reasonably smooth which as many of you know is not normally how these things go. Well this was no exception with everything re-fitted and nearly ready to go, oil and coolant loaded back into the engine. We primed the oil to get some round the engine, only to discover a big oil leak!!

Oil was sitting on top of the block and all over the back of the engine dripping down by the turbo! oh noes!!

We quickly worked out that the only place that it could be coming from was from the hard oil feed line that pumps oil to the turbo.. this as many of you know is a bit of pig to get to. The world almost ended!!

Knowing there was no other choice we set about removing everything off the top of the block (AC pipes, manifold, turbo and water cross over pipe) to find the offending item. We had re-used the original line that came with the new engine but it was sat at the wrong angle for my turbo. We had previously warmed it all up and bent it into position but by doing so we had inevitably cracked it. Not easily visible as the crack was facing towards the block/turbo but clearly visible when removed.

By the time we had finally got everything back together, once again primed the system, gapped/fitted the plugs, re-filled with coolant and turned the key.... there was an overwhelming sense of relief as she fired into life instantly and oh what difference.. its very quiet, I'm not used to this virtually no slap business

Somewhere in the above 25 hour marathon I also managed to fit the new rear pads and swap the diff oil out for some nice LS Millers stuff

Due to the extra time to remove and re-fit everything we ran out of time for mapping but will get this done in the very near future.

Say hello to 8k RPM rev limit and aggressive cam profiles!